Abrasive Blasting Services

Abrasive Blasting Facts

-

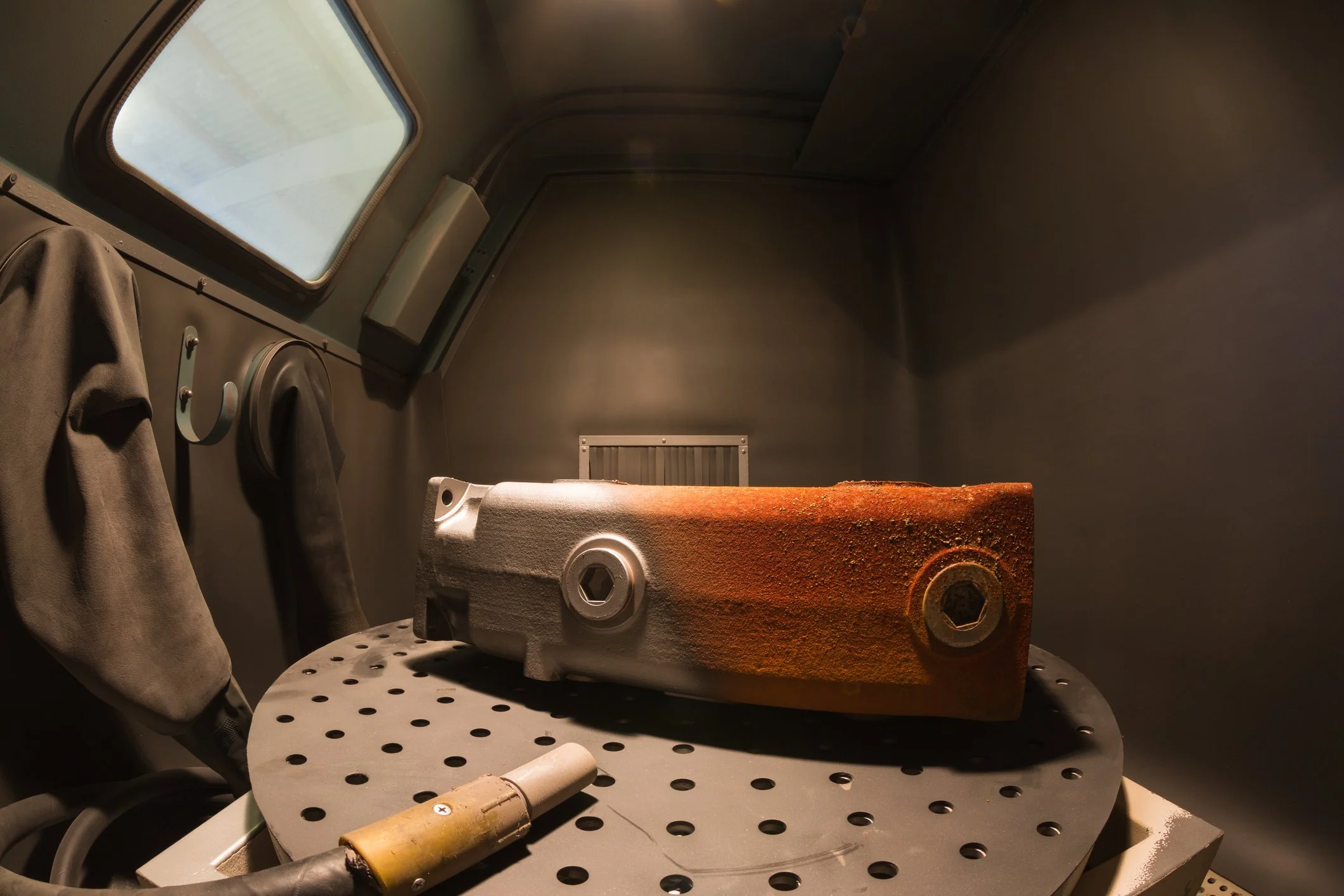

Abrasive Blasting is a process that cleans or smooths metal and plastic surfaces by blasting them with small, rough particles known as Media.

Our advanced air and wheel blasting systems remove rust, scale, paint, and contaminants while achieving consistent surface textures ideal for coating.

-

Metals commonly blasted with media for air, wheel, and sand blasting services include:

Aluminum

Steel

Stainless steel

Brass

Copper

Cast iron.

Magnesium

The choice of blasting media and method depends on the metal type and the desired surface profile to ensure optimal cleaning without damaging the substrate.

Engineered Finishing Inc. tailors blasting services to meet the specific requirements of each metal to achieve high-quality results with precision and care.

-

Blasting services utilize a variety of media depending on the application, material to be treated, and desired finish.

Aluminum Oxide – Aggressive cutting; used for cleaning, deburring, and surface preparation on hard metals.

Glass Bead – Produces a smooth, bright, satin finish, ideal for cosmetic finishing and stress relief.

Crushed Glass – Environmentally friendly alternative to silica; used for cleaning and light profile creation.

Silicon Carbide – Very hard and sharp; for rapid material removal and etching.

Plastic Media – Gentle; used for paint stripping and delicate substrates (aluminum, composites).

Walnut Shells – Organic and non-abrasive; ideal for cleaning softer metals and removing coatings without surface damage.

Corn Cob – Similar to walnut shell; gentle cleaning and polishing of soft metals or plastics.

Garnet – Durable and sharp; for general-purpose cleaning and surface prep.

Steel Shot – Spherical media for peening and creating a uniform, polished finish.

Steel Grit – Angular media for aggressive cleaning and rougher surface profiles.

Ceramic Bead – Long-lasting and consistent; provides a satin or peened finish on stainless steels and titanium.

Sodium Bicarbonate (Baking Soda) – Non-destructive; used for delicate cleaning and degreasing.

-

Steel Shot – Most common; used for peening, polishing, and achieving smooth finishes. Known as Shot Blasting.

Steel Grit – Angular steel particles for removing rust, mill scale, or coatings quickly.

Cut Wire Shot – Consistent shape and hardness; used for precision peening applications.

Stainless Steel Shot/Grit – Corrosion-resistant; ideal for non-ferrous metals and stainless components.

Chilled Iron Grit – Very hard and brittle; used for aggressive cleaning of tough surfaces.

Aluminum Shot – For non-ferrous parts requiring lower impact energy.

Types of Abrasive Blasting

-

Air Blasting - High-pressure air forces the abrasive media against the surface of the part, effectively cleaning, smoothing, or preparing it for further processing. This method ensures consistent coverage and precision in removing contaminants or rough edges.

Processes Available:

Automated Blasting

Tumble Blast

Cabinet Blast

Wet Blasting

Each process has unique functions and abilities. Reach out to us to figure out what works best for the parts you need finished.

-

Wheel Shot Blasting - These machines use a turbine wheel to accelerate media at high velocity for heavy-duty cleaning or surface conditioning. This process is used before painting or powder coating due to its ability to create a perfect rough surface for paint adhesion and bonding.

Processes Available:

Tumble Blast

Spinner Hanger

Wheel Table Blast

-

Sandblasting is a surface finishing process that propels abrasive material at high velocity using compressed air to clean, smooth, or etch a surface. The abrasive particles remove contaminants, rust, paint, or rough edges, leaving the substrate clean and prepared for further processing such as painting or coating.

Sandblasting is a type of air blasting process, but there are several variations within air blasting depending on the media used and the application:

Sandblasting: Traditionally uses silica sand as the abrasive media. It is effective for heavy-duty cleaning and surface preparation but has largely been phased out in many industries due to health and environmental concerns linked to silica dust.

Abrasive Blasting: A broader term that includes sandblasting but also utilizes alternate media such as aluminum oxide, glass beads, steel grit, walnut shells, or plastic beads. Each media varies in aggressiveness, finish quality, and suitability for different materials.

Bead Blasting: Uses small glass beads to create a smooth, matte finish without significantly removing surface material. It is less aggressive compared to sandblasting and is often used for cleaning delicate parts or finishing.

Shot Blasting: Involves propelling steel shots or grit at the surface, commonly used in heavy-duty applications such as removing scale or preparing metal surfaces in foundries and fabrication.

Compared to other air blasting methods, sandblasting is generally more aggressive and better suited for heavy-duty material removal but carries greater environmental and safety risks due to silica dust. Other air blasting processes use media tailored for specific finishes or gentler surface treatment while maintaining efficient cleaning and preparation capabilities.

Benefits and Industries

-

Efficient removal of rust, paint, and coatings

Preparation of surfaces for better adhesion of paints and coatings

Enhances surface texture for improved bonding

Cleans hard-to-reach areas and complex shapes

Increases durability and lifespan of metal parts

Environmentally friendly with recyclable media options

Fast process suitable for large-scale and small projects

Improves aesthetic appearance of finished products

Reduces need for chemical cleaning agents

Can be tailored with different media for specific surface requirements

-

Tooling and Fixtures: At Engineered Finishing Inc., we fabricate custom tooling and fixtures designed to hold and support your parts securely throughout the finishing process. Our precise fixtures ensure consistency and accuracy, allowing us to achieve the exact finish you require.

Masking and Plugging: we provide masking and plugging services to protect specific areas of your parts, effectively guiding where the finishing work is applied. This targeted approach minimizes waste, prevents damage to critical surfaces, and helps deliver superior quality results tailored to your specifications.

-

Automotive Industry

Engine components, chassis, and body parts require abrasive blasting to remove rust, old paint, and surface contaminants.

Media choice ensures effective cleaning without damaging delicate parts; e.g., plastic or walnut shell for gentle cleaning, aluminum oxide for tougher surfaces.

Aerospace Industry

Critical aircraft parts such as turbine blades and landing gear require precise surface preparation.

Using softer media prevents damage to thin metals and maintains structural integrity.

Manufacturing and Heavy Equipment

Gearboxes, valves, and heavy machinery components need blasting to remove scale, rust, and corrosion before coating or inspection.

Coarser media provide aggressive cleaning for thick layers, while finer media are used for delicate finishing.

Medical Device Industry

Surgical instruments and implants require abrasive blasting for surface texturing and cleaning to ensure biocompatibility.

Non-metallic or fine glass bead media prevent surface pitting or contamination.

Electronics Industry

Components like connectors and housings require precision cleaning to remove contaminants without damaging sensitive parts.

Micro-abrasive or soft-bead media maintain pristine surfaces.

Oil and Gas Industry

Pipes, fittings, and drilling equipment need abrasive blasting to remove scale, rust, and coatings before inspection or recoating.

Media selection balances cleaning aggressiveness and preservation of metal thickness.

Construction and Restoration

Structural steel, bridges, and historic metalworks are blasted to prepare surfaces for repainting or restoration.

Variety of media like silica sand or garnet are chosen based on surface hardness and desired finish.