"Excellence in Finishing, Engineered for You"

Our Services

-

Abrasive Flow Machining (AFM)

Abrasive Flow Machining (AFM) is an advanced metal finishing process ideal for achieving precise and consistent internal surface finishes on complex parts. This technique is especially beneficial for Additive Manufacturing (AM) components, which often feature intricate internal geometries that are difficult to finish using conventional methods.

-

Precision Air Blasting & Texturizing

Precision air blasting and texturizing uses high-velocity air mixed with abrasive media (Aluminum Oxide, Glass Bead, etc.) to clean, prepare, or texture metal or plastic surfaces. This method ensures uniform treatment by precisely targeting abrasive particles, removing contaminants, rust, and scale, while enhancing adhesion for coatings. We offer automated, hand/manual, and wet blasting services to fit your needs and finish preferences.

-

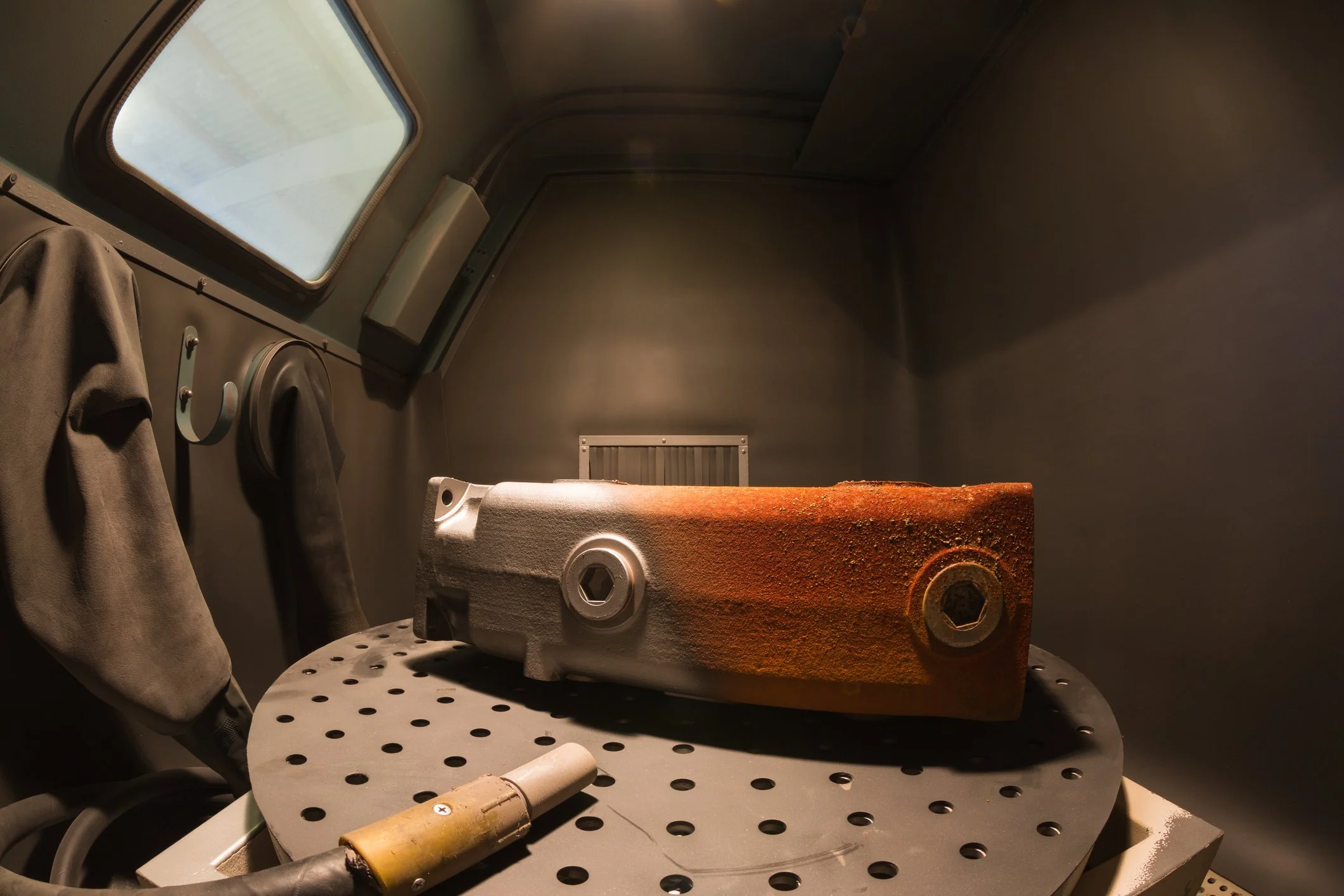

Stainless Steel Shot Blasting (Wheel Blasting)

Wheel blasting is a highly effective metal finishing process that uses high-velocity stainless steel shot propelled by a rotating wheel. This technique thoroughly cleans, strengthens, and prepares metal surfaces for subsequent finishing steps. Our specialty is providing comprehensive blasting options, such as tumbling, spinner hanging, and table wheel blasting.

-

Vibratory Tumble Deburring & Polishing

Vibratory tumbling and polishing is used to deburr, smooth, and enhance the finish of parts. This process is ideal for large quantities. We use vibratory bowls, barrels, and continuous machines with various media like porcelain, plastic, synthetic, and ceramic to match your needs. This ensures quality results and fast turnaround, reflecting our dedication to excellent service and part quality.

-

Precision Hand Deburring/Sanding

The precision hand deburring process involves skilled technicians meticulously and consistently removing sharp edges, burrs, and imperfections from metal or plastic components to ensure the exact finish you are looking to achieve. We also have the ability to fill holes or correct issues caused from the casting processes.

-

Sand Blasting

This abrasive blasting process offers exceptional surface preparation and finishing. We eliminate contaminants and imperfections for optimal coating adhesion. We utilize this service when we have large parts that aren’t able to fit in the hand or automated machines. Grit sizes vary and we can obtain any media you may need for your project.

-

Outsource Partnerships & Services

We have meticulously built a strong network of reliable and trustworthy partners that offer a wide range of quality services that compliment what we do and what our customers need. Whether it is for coatings, chemical finishing, or any services we do not offer, we can help get your project and parts through seamlessly.

-

Value-Added Services

Value-added services at Engineered Finishing. enhance our core offerings, providing customers with tailored solutions that improve efficiency, reduce costs, and ensure superior quality throughout. Just ask and we will do our best to get you what you need. Whether it is masking, plugging, expediting or something unique, we love solving issues and problems.

Industries We Serve

At Engineered Finishing Inc., we firmly believe that collaborating with companies across a diverse range of industries is essential to fostering growth and innovation in the United States and especially in Minnesota, our home state.

Where to Find Us